The Transformative Power of Green Mirror Finish in Metal Fabrication

In the modern world of metal fabrication, aesthetics and functionality go hand in hand. Among the various finishes available, the green mirror finish stands out as a beacon of innovation and sustainability. This article delves into the essence of the green mirror finish, exploring its advantages, applications, and the way it is shaping the future of the metal fabrication industry.

Understanding the Green Mirror Finish

The green mirror finish refers to a unique surface treatment applied to metals that gives them a reflective, glossy appearance with an environmentally friendly twist. This finish is achieved through a series of processes that not only enhance the visual appeal of the metal but also contribute positively to the environment. The green aspect signifies the use of eco-friendly materials and methods that minimize environmental impact.

Benefits of Using Green Mirror Finish in Metal Fabrication

Incorporating the green mirror finish into metal products offers a multitude of benefits:

- Aesthetic Appeal: The high-gloss, reflective nature of the green mirror finish elevates the look of metal products, making them visually striking and desirable.

- Sustainability: This finish is achieved using environmentally sound practices, which reduces the footprint associated with traditional metal finishing methods.

- Durability: Metal products with a green mirror finish are not only aesthetically pleasing but also resilient, often resisting scratches and corrosion.

- Easy Maintenance: The smooth surface of the green mirror finish makes cleaning effortless and promotes longevity in appearance and quality.

Applications of Green Mirror Finish in Various Industries

The versatility of the green mirror finish allows it to be employed across numerous sectors. Here are some notable applications:

1. Architecture and Interior Design

In architecture, the green mirror finish is utilized for decorative panels, railings, and facades. Its reflective quality can amplify natural light, creating an inviting environment. Interior designers harness this finish for fixtures, furniture, and accents, enhancing elegance and modernity.

2. Automotive Industry

Automakers are embracing the green mirror finish for both functional and aesthetic components. The striking reflection and durability help parts withstand the rigors of use while maintaining visual appeal, crucial for branding and customer attraction.

3. Consumer Electronics

Devices like smartphones, laptops, and appliances often feature metals treated with a green mirror finish. This not only provides a premium look but also protects surfaces from minor wear and tear.

4. Art and Sculpture

Artists and sculptors utilize the green mirror finish to add a contemporary touch to their creations. The reflective quality engages viewers differently, transforming simple objects into immersive experiences.

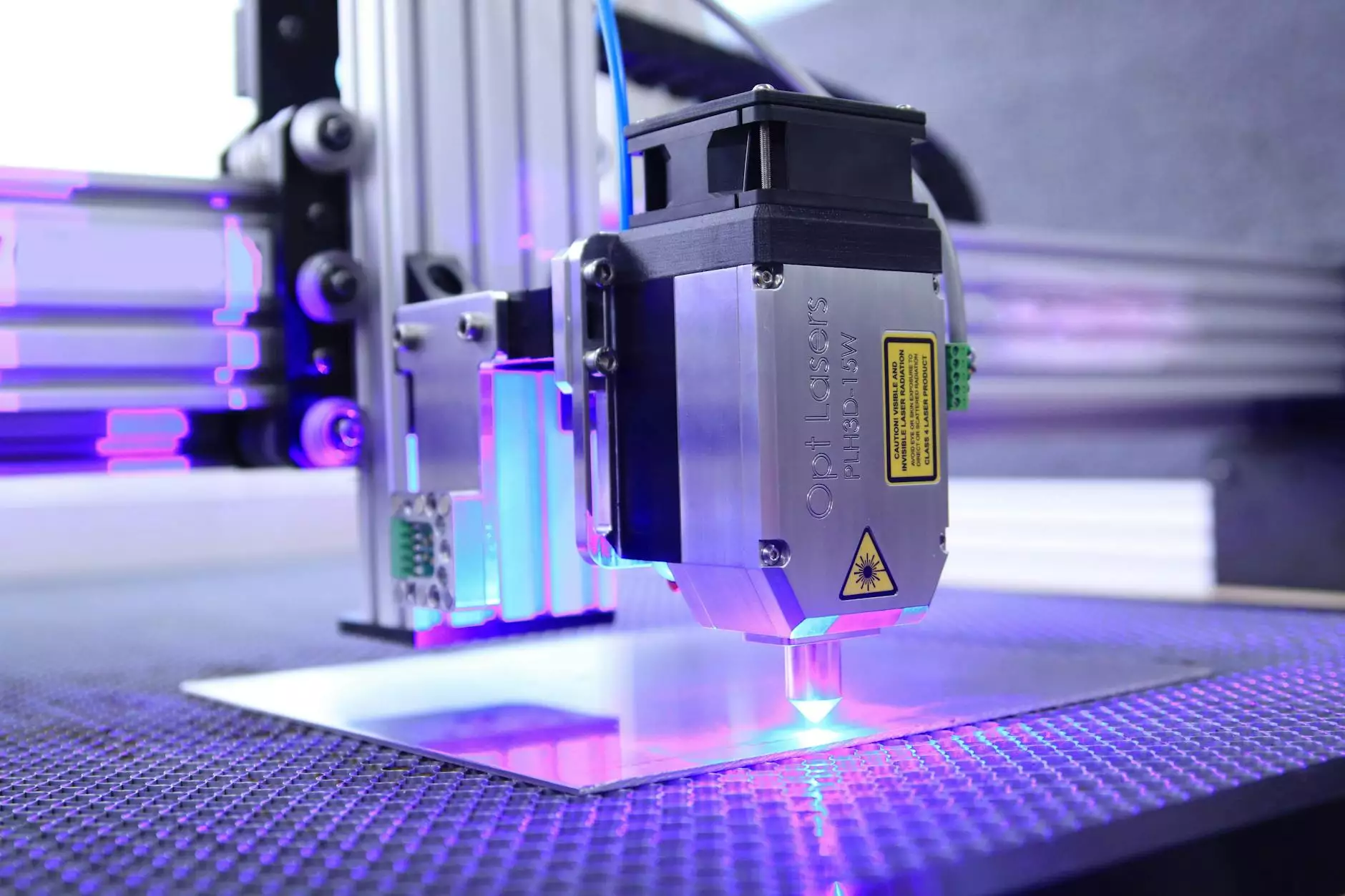

The Process Behind Achieving a Perfect Green Mirror Finish

Creating a perfect green mirror finish involves meticulous steps:

1. Surface Preparation

The first step is to clean the metal surface thoroughly. Any dirt, grease, or corrosion must be removed to ensure that the finish adheres properly and uniformly.

2. Polishing

Next, the metal surface undergoes a polishing process. This is critical as it determines the final finish. Specialized equipment is often used to achieve a mirror-like sheen.

3. Eco-Friendly Coating Application

After polishing, an eco-friendly coating is applied. This coating not only enhances the glossy appearance but also provides additional protection against environmental factors.

4. Curing

The coated metal is then cured, allowing the surface to bond effectively, thereby ensuring durability and longevity of the finish.

Environmental Impact of Using Green Mirror Finish

1. Reducing Waste

Traditional metal finishing processes often generate a substantial amount of waste. The green mirror finish is crafted using sustainable practices that minimize waste and promote recycling of materials.

2. Hazardous Chemicals

Many conventional finishes rely on hazardous chemicals that can be detrimental to health and the environment. In contrast, the green mirror finish employs environmentally friendly alternatives, aligning with eco-conscious manufacturing.

3. Energy Efficiency

The processes involved in achieving the green mirror finish are designed to be energy efficient, reducing fossil fuel consumption and lowering the carbon footprint of metal fabrication.

Choosing the Right Metal Fabricator for Green Mirror Finish

When seeking to incorporate a green mirror finish into your project, selecting the right metal fabricator is paramount. Here are key considerations:

- Experience: Look for a fabricator with a proven track record in delivering high-quality finishes.

- Certifications: Ensure they possess relevant certifications that validate their commitment to sustainable practices.

- Portfolio: Review their previous projects to gauge the quality of workmanship and attention to detail.

- Customer Service: A reliable fabricator will offer transparency, support, and guidance throughout the fabrication process.

Future Trends: The Rise of Eco-Friendly Finishes

The shift towards sustainability in metal fabrication is not just a trend but a fundamental change. The green mirror finish epitomizes this movement, prompting further innovations in eco-friendly practices. As businesses increasingly adapt to consumer demands for responsible production, it's predicted that:

- Advanced Technologies: The integration of new technologies will enhance the quality and efficiency of eco-friendly finishes.

- Wider Adoption: More industries will begin utilizing the green mirror finish as awareness of its benefits grows.

- Collaboration for Sustainability: Partnerships between fabricators and suppliers will focus more on sustainability, creating a circular economy in metal production.

Conclusion

The green mirror finish is not just a superficial enhancement in metal fabrication; it represents a significant leap towards sustainability, aesthetics, and durability. As businesses like Goldecosteel.com adopt and promote such innovative techniques, they pave the way for a brighter and more environmentally responsible future. By choosing the green mirror finish, companies not only elevate their products but also contribute positively to the planet, ensuring a blend of style and sustainability.